Hadrian console

Inspired by Northumbria's landscape and heritage, the Hadrian console from designer Fiona Barratt-Campbell is structural, solid and entirely unique.…

“A lot of my inspiration comes from nature,” says Fiona Barratt-Campbell, the Northumbrian designer behind Fiona Barratt Interiors and more recently furniture label FBC London. “We have a house in the Northumberland countryside and I like to walk there and along the beach. I’m also inspired by Roman history. I grew up near Hadrian’s Wall and we were always being taken to Roman ruins when I was at school.”

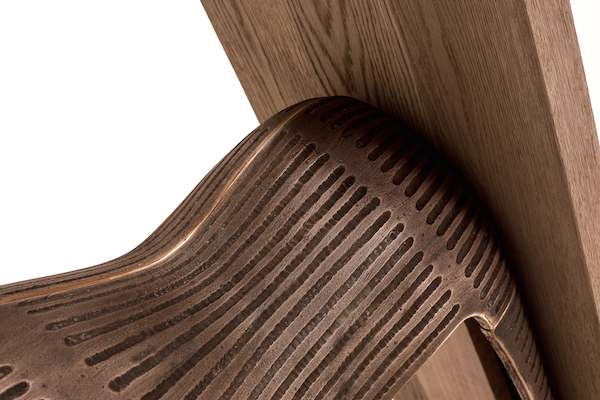

The Hadrian console, part of her first furniture collection for FBC London, encapsulates her Northern spirit perfectly. Named after the Roman emperor most famous for the wall he built, the console has a solid cast bronze base and sandblasted oak top. Like the rest of her collection, it combines a mix of different textural finishes, is solid and sculptural, and entirely unique.

“We work with a foundry in Northumberland, William Lane,” Barratt-Campbell tells us, explaining that the company was founded in 1862 and traditionally had been making nuts and bolts for warships. “Without their knowledge we wouldn’t have been able to produce many of these pieces.”

The Hadrian console took the longest in the collection to make. “It takes a lot of man hours to make it,” she says. “When it comes out of the bronze casting, it has really sharp edges that all need to be sawn off, either by hand or machinery, a metal grinder. Then there is the antiquing. People think that pieces just fall out perfect from the casting mould, but there is so much finishing on it which all needs to be done by hand.”

For Fiona, the provenance of her pieces is particularly important so each item is made in the UK, more specifically the North. “It is really important to me that my collection comes from the UK, particularly the North,” she says. “We are launching the FBC brand in the US, in LA in March 2014. The American company who approached us said that they still want everything to come from the UK because they love the provenance of it. This is important for me and why I said yes.”

Each piece in the collection takes anywhere from 10 to 12 weeks to make, but with individual customisations, the lead times become longer. “Every piece can be completely bespoke but obviously bespoke pieces take slightly longer, about 16 weeks,” Barratt-Campbell explains. “But for what goes into it, it is relatively quick.”

SuperyachtDesign talks to Fiona Barratt-Campbell in Q21 for Artisan. To subscribe and received this issue, plus future issues of SuperyachtDesign as well as gain access to exclusive online content, click here.

NEW: Sign up for SuperyachtNewsweek!

Get the latest weekly news, in-depth reports, intelligence, and strategic insights, delivered directly from The Superyacht Group's editors and market analysts.

Stay at the forefront of the superyacht industry with SuperyachtNewsweek

Click here to become part of The Superyacht Group community, and join us in our mission to make this industry accessible to all, and prosperous for the long-term. We are offering access to the superyacht industry’s most comprehensive and longstanding archive of business-critical information, as well as a comprehensive, real-time superyacht fleet database, for just £10 per month, because we are One Industry with One Mission. Sign up here.

NEW: Sign up for

SuperyachtNewsweek!

Get the latest weekly news, in-depth reports, intelligence, and strategic insights, delivered directly from The Superyacht Group's editors and market analysts.

Stay at the forefront of the superyacht industry with SuperyachtNewsweek