After takeovers, Reckmann strives for new growth

Last year - 2013 - provided Reckmann, the German yacht rigging specialist an opportunity to expand their product lines with two business takeovers. Now, the MD says, they’re focusing on growth…

In a year that was marked by continued caution, Reckmann’s move to diversify its portfolio into hydraulics and in-boom furlers was a refreshing sign of entrepreneurial moxy. The firm, which supplies all kind of headsail furling gears to Northen European yards like Royal Huisman, Baltic, Nautor and Vitters, as well as the Kiwi yards and many mast-makers, is recognised as an industry leader in superyacht equipment, mainly headsail furler and rigging solutions. The new acquisitions increase its presence in the sailing superyacht market.

Both the Holmatro and the NSM were quick turnarounds, facilitated by the familiarity Reckmann’s MD, Marcus Schuldt already had for their products and by the ease of the mutual agreements. “The Holmatro deal was done in a couple of weeks, as was NSM,” Schuldt says. “We didn’t have enough individual boat projects to work on, so we thought it would be a good idea to find a way to extend our product portfolio and put more equipment on each yacht. Also, it provides us a closer contact with our clients.”

Schuldt is the latest in a family line to run the 122 year old rigging firm, whose heritage includes rigging Gustav Eriksson’s Flying P line of square-rigged cargo ships in the 1930s—the greatest expression of commercial-grade sailing in history. Few suppliers or contractors in the superyacht market can claim such a history, and yet, Reckmann also displays a nimble business stance, led by Schuldt, continuing to innovate under pressure.

“We’ve already got orders for our new boom drives, even as we’re still completing the refreshed design after the acquisition of NSM,” Schuldt says. “We need to supply them in April.”

Schuldt sees the benefits of targeting and owning a niche market—Reckmann’s being the world’s most advanced sail furling systems. He admires Baltic shipyard for their niche approach: “They produce a very special product, so they too have isolated a real niche they’ve been able to exploit,” he says. With their new portfolio, Reckmann is positioned as a one-stop shop for advanced furling solutions.

Still it’s a challenging market. “We have a slightly increased number of superyachts we’re working on, but the market is still not as it was in 2005-7,” Schuldt says. “But it’s okay. We have challenging bigger projects like the 85m Vitters-Oceanco for which we’re supplying a completely new furling drive for the end of this year.”

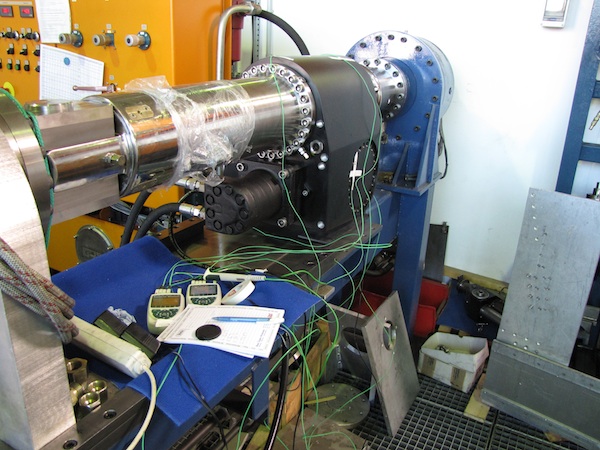

When Schuldt took over the business from his father 23 years ago, Reckmann had around 8 different manual and hydraulic furler designs. Today they have 35, including electric, hydraulic and manual models, under- and on-deck models, in-boom, in-mast, and with a host of innovations the company pioneered, like a cunningham option for furling gears, carbon and aluminium foils. They just completed a stock-taking and the company warehouses 15,000 articles.

“The market for boats up to 25m is a real problem. The business went down 60 to 70 per cent, and that’s a mater of fact. That’s a bit of a problem for us because we supply equipment to boats from about 40 foot and up. The business where we used to supply full mast, furling and rigging packages to these clients has almost completely gone. So we’re now focused more and more on niche markets where the client needs a real specialist.”

Reckmann has gotten into special developments for the German Navy, supplying parts to the submarines and the company is currently developing parts for German-built frigates. They’ve also started working in the shading system field.

Reckmann is high-spec stuff, and Schuldt has good relationships with most of the custom sailing superyacht yards worldwide. The current stalling of orders placed in New Zealand has constrained one of Reckmann’s formerly consistent routes to sale. “The problem is they’ve had a few orders cancelled in the last two years, which is a problem for some boatyards, and the situation is still not good there. There are very few sailboats in build. We’re only supplying to the new Mondango project in New Zealand at the moment.”

In their facility north of Hamburg, the company’s 35 employees design, develop, assemble, test, and market their range of products. “But we don’t have expensive CNC machines,” Schuldt says. “We have an inventory, but we have our parts manufactured by our trusted partners who are located close to us, and we assemble here in our workshop.”

Schuldt says that clients, including project managers on new builds, specify Reckmann kit specifically, as a result of the company’s focus on making those contacts and establishing the name of the firm. “We have very good connections with the most important consultants and designers,” Schuldt says. “We introduce our products to them and we solicit their opinions on what we’re designing and delivering, seeking to offer what they need and improve our current lines of products. The last thing a consultant or advisor wants is trouble with their client, so we find they’re happy as a result to go with a proven, established system and manufacturer like Reckmann.”

“The discussion I always have—and it’s probably one of the most common in our industry—is about paying for quality. On a 40m boat for instance, if our package is 10 or 20 thousand Euros more expensive than an alternative, you can say, okay, 20 thousand is a lot or money, yes. But if you consider that the running costs of a 40m can be 5 thousand a day, then we’re talking about the equivalent value of four days’ operations. If you have one failure with the cheaper equipment where you lose a couple of days at a regatta or a week of charter, that’s costly.”

Indeed, Reckmann’s equipment is known for it’s robust, yet slick and clever German engineering. Their RF90 hydraulic furler is nearly iconic in its design and is currently specified and installed on many of the newest, largest sailing superyachts. To this, they now add NSM’s boom drives and Holmatro’s rigging hydraulics.

For 2014, Schuldt says they’re busy streamlining the products, design and operations. To improve efficiency, the company is integrating a new computer system and will reorganise the workshop to make the production smoother.

We will stand by to cover their latest work, including the furling systems for the new 85m Vitters-Oceanco project.

Zefira underway at the Dubois Cup, 2013.

Profile links

NEW: Sign up for SuperyachtNewsweek!

Get the latest weekly news, in-depth reports, intelligence, and strategic insights, delivered directly from The Superyacht Group's editors and market analysts.

Stay at the forefront of the superyacht industry with SuperyachtNewsweek

Click here to become part of The Superyacht Group community, and join us in our mission to make this industry accessible to all, and prosperous for the long-term. We are offering access to the superyacht industry’s most comprehensive and longstanding archive of business-critical information, as well as a comprehensive, real-time superyacht fleet database, for just £10 per month, because we are One Industry with One Mission. Sign up here.

NEW: Sign up for

SuperyachtNewsweek!

Get the latest weekly news, in-depth reports, intelligence, and strategic insights, delivered directly from The Superyacht Group's editors and market analysts.

Stay at the forefront of the superyacht industry with SuperyachtNewsweek