Future Fibres relocates innovation to Salisbury

With a significant new facility now open for reasearch into novel forms of carbon composites, Future Fibres is placing significant capital into R&D. SuperyachtNews.com speaks with Innovation Centre director, Humphrey Bunyan on their plans for the future.…

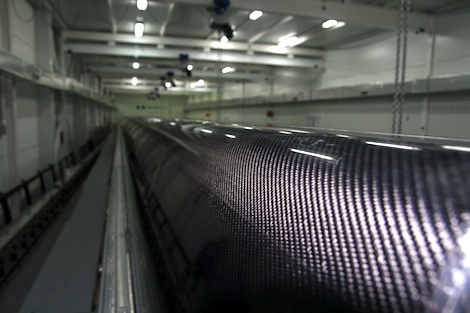

Future Fibres, Tom Hutchinson’s carbon-composite rigging enterprise, based in Valencia, recently announced that it would open an R&D facility in Salisbury, England. Heading up the new 5,000m2 research facility is Hutchinson’s cousin, Humphrey Bunyan, whose enthusiasm for the potential of carbon composite structures in yachting, as well as automotive and construction industries, is infectious.

Bunyan had originally developed the manufacturing processes for Future Fibres, and has headed up R&D for new products. Over a ten year period, with Future Fibres’ product line expanding to cover various rigging and now spars, Bunyan found his time was increasingly pulled into supporting the existing products.

The move has been facilitated by the arrival last year of new CEO Hugues Jacquemin, and represents a significant restructuring of the company’s research capabilities.

“This new facility is really about innovation, so we’ll be looking at new products and processes, bringing them in and seeing where they can be applied,” Bunyan told SuperyachtNews.com exclusively. “We have really good team of guys in the R&D department at the manufacturing plant and head office in Valencia, Spain, who are still there, supporting our products, while with this facility, we can get on and develop the next round of products.” The new facility will be able to test 110 tonne break strength cables, impregnate fibres, test and apply novel formulations of epoxies, so that Bunyan’s team can create their own matrix for carbon. “We’ll be able to make prototype pieces of rigging and whatever else we fancy,” he said.

Bunyan explained that with Future Fibres’ work with superyachts, in which each order is unique, he was being taken away from pure R&D work. The relocation to Salisbury is intended refocus his energies on helping develop the next generation of products for the company.

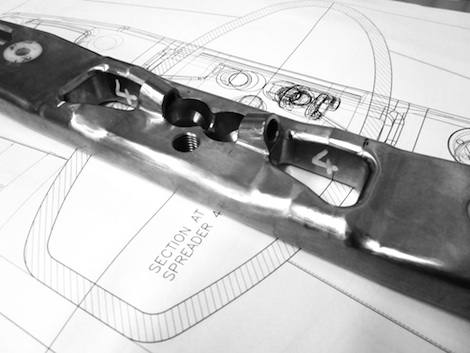

“We’re working on new rigging design and constantly pushing the leading edge of that,” he said. “We’re constantly studying and testing the rigours of sailing. Obviously superyachts are enormously expensive technology-focused products. We want to make our products last longer, as well as making them look fantastic on the boat, and helping to improve the weight distribution so clients get a faster, more comfortable ride.”

The facility is just gearing up for work now, but Bunyan is ambition with their long-term goals. “My vision for this place is we’ll be looking at carbon composite structures throughout the whole boat—not just the rigging. That’s where we’ll end up, I hope.”

Bunyan is particularly focused on the emerging thermo-plastic technologies. “We’re pushing very hard to get carbon and thermoplastic together in the composite world,” Bunyan explained. “Thermoplastic has some interesting aspects for us from a cable-point of view in terms of terminations and how we can join cables totether. Also the turnaround time of thermoplastic is potentially a lot faster than current curing times. The automotive industry is really interested in taking sheets of carbon that’s cured with thermoplastic instead of an epoxy resin. You can heat these sheets up with an infrared light or heat source; the sheet becomes pliable, and you can stamp it like you can with metal and achieve a shape almost instantly. It’s an order of magnitude easier than what currently happens with infusion, and potentially presents a wide range of materials to choose from depending on temperatures and stiffness, and opportunities for recycling. It’s an exciting time.”

With existing contracts out with Formula 1 racing teams (for which Future Fibres manufactures the shock absorption cables which keep the wheels attached to the chassis in the event of a crash) and new ideas for company expansion into non-sailing areas like construction cranes, the new focus on R&D with a base in the UK looks like a smart move for the business. “I really want the composite gurus to come here and test ideas out and exchange notes,” Bunyan explained. “Ultimately we’re here to solve problems.”

Bunyan had originally developed the manufacturing processes for Future Fibres, and has headed up R&D for new products. Over a ten year period, with Future Fibres’ product line expanding to cover various rigging and now spars, Bunyan found his time was increasingly pulled into supporting the existing products.

The move has been facilitated by the arrival last year of new CEO Hugues Jacquemin, and represents a significant restructuring of the company’s research capabilities.

“This new facility is really about innovation, so we’ll be looking at new products and processes, bringing them in and seeing where they can be applied,” Bunyan told SuperyachtNews.com exclusively. “We have really good team of guys in the R&D department at the manufacturing plant and head office in Valencia, Spain, who are still there, supporting our products, while with this facility, we can get on and develop the next round of products.” The new facility will be able to test 110 tonne break strength cables, impregnate fibres, test and apply novel formulations of epoxies, so that Bunyan’s team can create their own matrix for carbon. “We’ll be able to make prototype pieces of rigging and whatever else we fancy,” he said.

Bunyan explained that with Future Fibres’ work with superyachts, in which each order is unique, he was being taken away from pure R&D work. The relocation to Salisbury is intended refocus his energies on helping develop the next generation of products for the company.

“We’re working on new rigging design and constantly pushing the leading edge of that,” he said. “We’re constantly studying and testing the rigours of sailing. Obviously superyachts are enormously expensive technology-focused products. We want to make our products last longer, as well as making them look fantastic on the boat, and helping to improve the weight distribution so clients get a faster, more comfortable ride.”

The facility is just gearing up for work now, but Bunyan is ambition with their long-term goals. “My vision for this place is we’ll be looking at carbon composite structures throughout the whole boat—not just the rigging. That’s where we’ll end up, I hope.”

Bunyan is particularly focused on the emerging thermo-plastic technologies. “We’re pushing very hard to get carbon and thermoplastic together in the composite world,” Bunyan explained. “Thermoplastic has some interesting aspects for us from a cable-point of view in terms of terminations and how we can join cables totether. Also the turnaround time of thermoplastic is potentially a lot faster than current curing times. The automotive industry is really interested in taking sheets of carbon that’s cured with thermoplastic instead of an epoxy resin. You can heat these sheets up with an infrared light or heat source; the sheet becomes pliable, and you can stamp it like you can with metal and achieve a shape almost instantly. It’s an order of magnitude easier than what currently happens with infusion, and potentially presents a wide range of materials to choose from depending on temperatures and stiffness, and opportunities for recycling. It’s an exciting time.”

With existing contracts out with Formula 1 racing teams (for which Future Fibres manufactures the shock absorption cables which keep the wheels attached to the chassis in the event of a crash) and new ideas for company expansion into non-sailing areas like construction cranes, the new focus on R&D with a base in the UK looks like a smart move for the business. “I really want the composite gurus to come here and test ideas out and exchange notes,” Bunyan explained. “Ultimately we’re here to solve problems.”

Profile links

Click here to become part of The Superyacht Group community, and join us in our mission to make this industry accessible to all, and prosperous for the long-term. We are offering access to the superyacht industry’s most comprehensive and longstanding archive of business-critical information, as well as a comprehensive, real-time superyacht fleet database, for just £10 per month, because we are One Industry with One Mission. Sign up here.