Safety warning after mooring line failure

The MAIB has issued a Safety Bulletin to highlight urgent safety lessons that have arisen in the early stages of its investigation into the mooring line failure on board LNG tanker Zarga, which resulted in serious injury to a deck officer.…

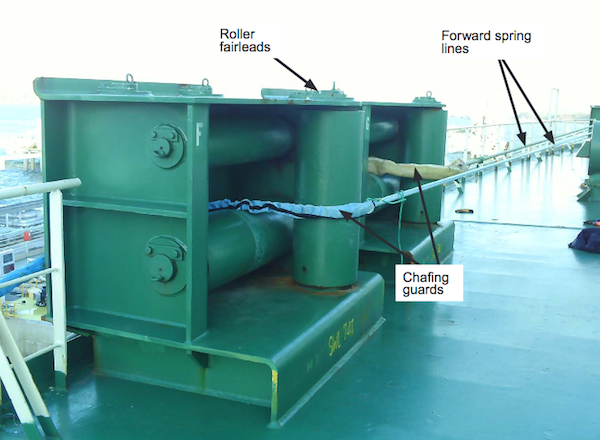

Zarga was declared all fast alongside about 40 minutes prior to the accident and the attending tugs were let go. The vessel subsequently moved out of position in the gusty wind conditions during which time the mooring teams were fitting chafing guards to the lines. As the tugs had already been released, the master instructed the officer of the forward mooring party to tension the forward spring lines to warp Zarga back into the correct position.

The officer positioned himself aft of the forward springs’ port-shoulder roller fairlead, and positioned a second crewman forward of him in order to relay his orders to the winch operator. As the winch operator attempted to heave in on the springs, the winch repeatedly stalled and rendered. After about 10 minutes, one of the spring lines began to rattle and creak, and then suddenly parted. The section of the line between the break and the port-shoulder roller fairlead struck the officer on his head as it whipped back before going overboard through the fairlead.

Mooring lines and winches

The 5-year old mooring lines fitted to the vessel were 44mm diameter sheathed ultra-high modulus polyethylene (UHMPE) with a length of 275m and a minimum breaking load (MBL) when new of 137t. The outboard ends of the UHMPE spring lines were fitted with 22m long Euroflex (polyester/polyolefin) tails, which had an MBL of 190t. The section of the UHMPE spring line in use between the winch and the connection with the Euroflex tail was about 68m long. The split drum type mooring winch had a 30.6 tonne-force (tf) winding pull, rendered at a load of 34tf and operated at 15m/minute.

Initial findings: elongation and snap-back

The amount a mooring line stretches depends on the elasticity of the material(s) used in its manufacture and the length under load. Elongation of the line introduces stored energy that, if suddenly released under load when the line parts, can cause the failed ends to recoil back towards their anchor points at high speed; this is referred to as snap-back. Both wire and high modulus synthetic mooring lines have low elasticity and, consequently, are

considered to have very little snap-back when they fail, and this is often considered to be an advantage over other types of synthetic line. However, although capable of handling high dynamic loads, low elasticity can make high modulus synthetic mooring lines prone to failure under peak dynamic loading.

On board Zarga,11m tails were originally fitted to reduce peak dynamic loading, but these were replaced with 22m tails after peak dynamic loads were experienced that had led to a series of line failures. However, the 22m tails had much greater elasticity and this, and the routeing of the line, introduced a significant snap-back hazard to the outer section of the failed UHMPE mooring line. The danger of snap-back was identified in the vessel’s risk assessments, but snap-back zones had not been marked on Zarga’s mooring decks. Because UHMPE mooring lines were fitted, the perception among members of the crew was that, in the event of a mooring line failure under load, the ends of a parted line would simply fall to the deck. In this case, the inboard section of the failed line recoiled a short distance towards the base of the winch.

Safety lessons

As a result of their initial findings, MAIB have issued the following findings:

• When connecting synthetic tails to UHMPE, HMPE and wire mooring lines, the energy introduced due to the elasticity of the tails can significantly increase the snap-back hazard.

• Elongation is proportional to the length of tail. Increasing the length of the tail will increase the amount of elongation and hence the amount of energy that can be stored in the line when under load.

• Ship owners/operators should ensure that the type of lines and tails used for mooring lines are suitable for the task and that the dangers of snap-back are fully considered.

• Mooring teams should be aware of the potential for snap-back in all types of mooring line, and the probable areas on the mooring deck that are not safe when lines are under load.

• Mooring lines led around roller pedestals and fairleads can lead to potentially complex snap-back zones. Ship operators and masters should conduct their own risk assessments to ensure potential snap-back zones are identified, and are reviewed at regular intervals.

• Notwithstanding the ongoing investigation into the nature of the failure of Zarga’s spring line, where doubt exists on the continued use of a mooring line, the vessel operator should obtain guidance from the rope manufacturer on the conduct of detailed line inspections.

The full safety bulletin can be read here.

NEW: Sign up for SuperyachtNewsweek!

Get the latest weekly news, in-depth reports, intelligence, and strategic insights, delivered directly from The Superyacht Group's editors and market analysts.

Stay at the forefront of the superyacht industry with SuperyachtNewsweek

Click here to become part of The Superyacht Group community, and join us in our mission to make this industry accessible to all, and prosperous for the long-term. We are offering access to the superyacht industry’s most comprehensive and longstanding archive of business-critical information, as well as a comprehensive, real-time superyacht fleet database, for just £10 per month, because we are One Industry with One Mission. Sign up here.

NEW: Sign up for

SuperyachtNewsweek!

Get the latest weekly news, in-depth reports, intelligence, and strategic insights, delivered directly from The Superyacht Group's editors and market analysts.

Stay at the forefront of the superyacht industry with SuperyachtNewsweek